Trims that Speak, Your Brand’s Language

A garment trim is more than just a small addition to a garment—it's a powerful tool for brand recognition. From concept to creation, we combine advanced echnology, premium materials, and expert craftsmanship to ensure that our trims enhance your brand’s identity and leave a lasting impression.

Label

Garment labels are widely classified into two types, depending on whether the designs are woven or printed: Woven Labels and Printed Labels.

Woven Labels

Woven Labels

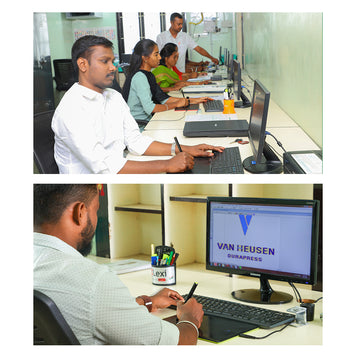

Designs are created using advanced textile CAD software specifically developed for label designing.

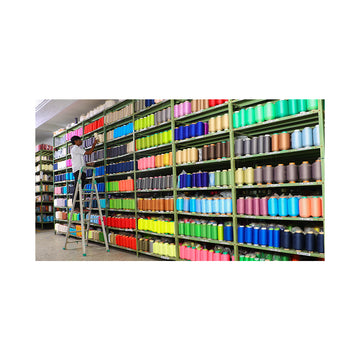

From our wide selection of over XXX shades of yarn, the exact shade is matched against the design. Up to 12 different colours can be woven into a single design.

The CAD design and the perfectly matched yarn shade are uploaded onto special Jacquard weaving looms imported from Switzerland and Italy. The raw material used for woven labels is polyester yarn. The warp yarn is primarily in two colours-black and white—while the weft yarn is used to weave the design and colours into the label. During this process, the label is woven in fabric form.

The woven label in fabric form is cut into vertical tapes using ultrasonic machines and folded into different styles as per customer requirements. Available folding styles include Straight Cut, End Fold, Mitre Fold, Center Fold, and Manhattan Fold. Additionally, woven labels can be cut into any shape using ultrasonic machines, allowing for a range of applications such as badges, zip pullers, and more.

All labels undergo stringent manual and automatic quality checks at each stage of production before being shipped to customers.

Printed Labels

Printed Labels

Labels can be printed on a variety of materials such as cotton tapes, taffeta tapes, tearable taffeta tapes, satin tapes, and more. Process: Tapes, either woven in-house or sourced externally, are printed on using specialized printing machines. Designs are created on design software, and a film or screen is developed for these designs. The designs are then printed using inks that meet all safety norms.

The initial process is similar to the above, but instead of printing on tapes, designs are printed on special papers and given a powder coating. These prints are then transferred onto garments by applying heat and pressure. This method is not limited to labels; it can also be used to print larger designs directly onto garments.

Elastics

Elastic tapes can be manufactured using either weaving or knitting techniques.The raw materials for both methods include nylon or polyester yarn, combined with a stretchable material such as elastane or natural rubber. The stretch and thickness of the elastic tape can vary depending on the materials and techniques used. Special finishes can also be applied to achieve the desired look and feel.

Types of Elastics

Types of Elastics

Knitted elastics are lightweight and commonly used in applications where the elastic tape is hidden within the fabric, earning them the name "inner elastics." These elastics are typically plain or feature simple patterns, as intricate designs cannot be achieved using this technique.

Woven elastics, also known as "outerwear elastics," are ideal for applications requiring intricate designs, thanks to advanced Jacquard technology. This makes them particularly popular in underwear requiring branded tapes and in athleisure products.

Qualities of Woven Labels

• Damask Labels: The most popular type of label, offering high versatility and the ability to achieve a high degree of detail. These labels have a smooth feel and are ideal for branding.

• Satin Labels: These labels are woven using the satin weave, giving them a velvety finish with a sheen look. Primarily used by luxury, bridal, and formal wear brands.

• Taffeta Labels: Low GSM and economical, these labels are primarily used for care labels.

• Needle Loom Labels: Woven directly as tapes rather than fabrics, eliminating the need to cut fabric vertically, which can sometimes cause rough edges. The woven edges provide a smooth finish that is gentle on the skin.

Special Labels

•Iron-On Labels: While most labels are sewn onto garments, iron-on labels feature a permanent adhesive on the back. By applying high temperature and pressure—or even using a household iron—the label adheres to the fabric in no time.

• Self-Adhesive Labels: Ideal for use on products like stationery, furniture, and more. These woven labels can be peeled and stuck to products just like regular stickers.

• Embossed Labels: These labels feature a raised pattern, creating a tactile and visual effect.

• Engraved Labels: The pattern is slightly sunken, giving the label a stamped appearance.

• Woven Badges: Woven labels can be cut into various shapes and used as badges to adorn garments. The edges can also be embroidered, making them suitable for uniforms.

• Puff Labels: These 3D woven labels, commonly used for zipper pulls, are filled with yarn to create a distinctive, pillow-like appearance.